FAQ Category - Finishes

Back To FAQWhat Diameter Rods do people usually use?

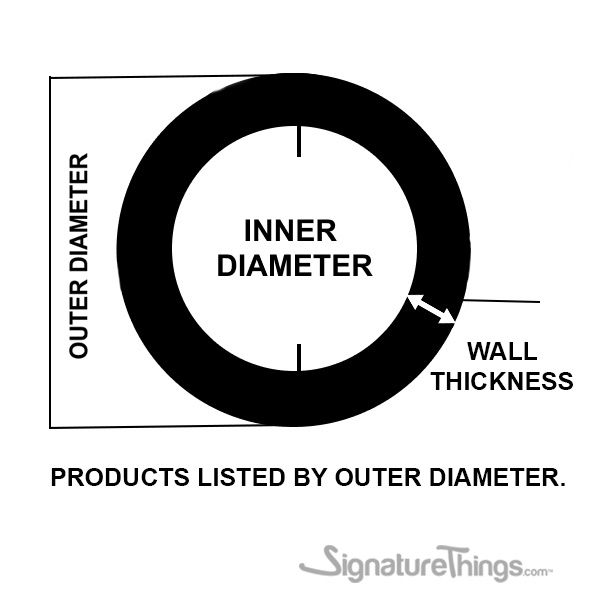

We can supply Brass hollow Rods in Multiple Diameters, Wall Thickness, lengths, and Finishes.

1) Diameters available : 3/8" , 1/2" , 5/8" , 3/4" , 1" , 1 1/4" , 1 1/2" and 2"

Lengths available : 6'-0" and 12'-0" We cannot ship larger then 7'-9" in an 8 foot package which requires additional shipping costs

We can cut these to sizes as per your measurements upto an 1/8" accuracy with laser cuter.

If you can provide us with CUT CLEAR sizes needed we can do a wastage analysis and build the cart for you

We can also factor in the flange and/or brackets you would like to use to provide accurate sizes.

We have a Tubing Connector, Splice which can be used on site to connect tubings to make them longer.

2) Thickness available: 0.040 mm (1/24") (standard), 0.050 mm (13/64") (standard) , 0.062 mm (1 /16") (thicker) , and 0.125 mm ( 1/8") (thickest)

Brass quality is Alloy 360 (Free Machining Brass)

3) Guideline recommendations for 1 1/4" D Tubing's, Your designer and contractor should make decisions per the project requirements.

1) 0.040 MM and 0.050 Standard rods should be supported at every 2 to 2 1/2 feet by center brackets

2) 0.062 MM Thicker rods should be supported at every 3 to 3 1/2 feet by center brackets

3) 0.125 MM Standard rods should be supported at every 4 1/2 to 5 feet by center brackets

4) Finishes: Custom Matched, Polished Brass, Polished Chrome, Polished Nickel, Satin Brass, Satin Nickel, Antique Brass, Oil Rubbed Bronze, Aged Brass, Un-Lacquered Polished Brass, Black Painted un-lacquered, and Dual Tone Finishes

Most People use 1 1/4" Diameter Rods for their Closets Rods, these work best for standard clothes hangers. 1" or 1 1/2" diameter work fine as well.

Picking the right Diameter and Wall Thickness has to do with the span of the opening, brackets used for mounting, mounting of the hardware to the wall, weight of clothes expected, is some sagging acceptable, and the desired look you are trying to achieve.

Brass Finishes impact on Shipping Times

We provide custom finish options on ALL our brass products. The Finish you pick has an impact on how soon the products will be ready for shipping. Some finishes are done inhouse and some have to go to the Platers for electronically plating. Here is a quick quide on the time it might take per order based only on finish choice. The other variables on shipping times are not factored in this list.. E.g. if it is a custom product it will need additional fabrication time, if the quantity is larger (10 or more) it will need additional time, etc.

Polished Brass is Lacquered. This is how most inventory is ready and stored in our factory

Polished Chrome does not need lacquer. It is Plated and may need 10 extra days after fabrication.

Polished Nickel does not need lacquer. It is Plated and may need 10 extra days after fabrication.

Satin Brass is Lacquered. This is done inhouse. We first delacquer the Polished Brass products then refinish then to Satin Brass then lacquer them. 5 extra days after fabrication

Satin Nickel does not need lacquer. It is Plated and need 10 extra days after fabrication.

Antique Brass is Lacquered. This is done inhouse. We first delacquer the Polished Brass products then refinish then to Antique Brass then lacquer them. 7 extra days after fabrication

Oil Rubbed Bronze is Lacquered. This is done inhouse. We first delacquer the Polished Brass products then refinish then to Antique Brass then lacquer them. 7 extra days after fabrication

Aged Brass is Un-Lacquered. This is done inhouse. We first delacquer the Polished Brass products then refinish then to Aged Brass. 5 extra days after fabrication

Un-Lacquered Polished Brass is Un-Lacquered. This is done inhouse. We first delacquer the Polished Brass products then refinish then to Aged Brass. 5 extra days after fabrication

Black Painted un-lacquered. This is done inhouse. We first delacquer the Polished Brass products then refinish then to Oil Rubbed Bronze, after that is dried we spray paint Black color. 10 extra days after fabrication

Dual Tone Finishes this depends on the products and the finishes. 10 extra days after fabrication